WELCOME TO VIJAY ENGINEERING

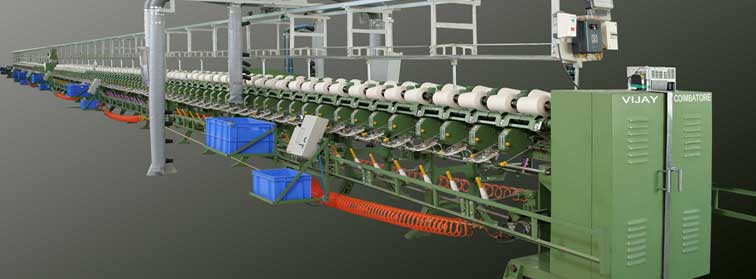

VIJAY ENGINEERING WORKS, founded in the year 1980, is today a global player and one among the manufacturers of the entire range of Textile Machinery.

The manufacturing Plant was started at COIMBATORE in TAMILNADU, one of the largest Textile Manufacturing zone in India.

History stands as a documented proof of VIJAY ENGINEERING WORKS Corporate and Financial success reflecting phenomenal growth since first year of operations. VIJAY ENGINEERING WORKS has 50% market share in the domestic Textile CONE WINDING AND POST SPINNING Machinery Industry. This machine was well accepted in the market and the Company started getting orders from all the corners of the country.

VIJAY GROUP OF COMPANIES diversified into RIG and is a brand leader in manufacturing customized products. VIJAY Foundry makes Precision Castings for own use.

The Company in its R&D designed and manufactured these machines with latest technology upgradation and by the year 1999, the Company manufactures various stated art machines which are marketed globally.

VIJAY GROUPS Global presence has grown over the years, with a market presence in developing countries.

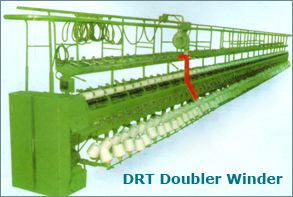

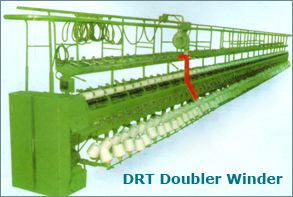

Manufacturing Machines

- High speed cone winding machine

- Slow speed cone winding machine

- Hank to cone winding machine

- Hank to cheess winding machine

- Soft package machine

- Reeling machine

- Ring doubling machine

- Bundling machine

- Any special type machine as per customer requirement.

HRD

Human Resource Development is an ongoing process at VIJAY ENGG. Training to all employees at all levels is imparted regularly. Employee involvement programs like Quality Circles have been underway for some time now and they have yielded very encouraging results.

A strong ancillary base has also been developed over the years. Most of the ancillary units work for VIJAY exclusively. Not only are they given technical assistance, but there is also a constant process of surveillance and quality audits done at their premises by VIJAY Engineers.

VIJAY GROUPS shall strive to achieve Environmental Excellence through:

Compliance with applicable legislative and other requirements and go beyond compliance to good practices on environmental management

Periodic reviews of its environmental performance and minimizing the environmental impacts, while achieving its business objectives

Protection of air, water, land and biodiversity and engaging with the community and business associates on environmental issues of mutual interest

Waste minimization, energy conservation and recycle and reuse of resources like water and sand

Provision of management tools, awareness and training to employees for continual improvement in its overall environmental performance.

CONTACT US

VIJAY ENGINEERING WORKS

53, B-5, P.N.Palayam Road, K.R.Puram,

Ganapathy, Coimbatore - 641 006.

PH: 2561045, 2561776

FAX: 91-0422 -2561776

VIJAY Manufacture

Soft package Winder machine

Hard package Winder machine

Hank to Cone Winder machine

Hank to Cheese Winder machine

HIGH SPEED CONE WINDING MACHINE

GENERAL SPECIFICATIONS

- No. of Spindles:8 to192 Spindles (or in multiples of 8 Spindles upto 192 Spindles).

- Package Option:The Machine is suitable to wind 3.30 / 5.57 / 4.20 Paper / Plastic Cones.

- Yarn Suitability: Cotton / Synthetics / Blended or Woolen Yarn.

- Winding Speed: A Choice of 3 Speeds 600 / 700 / 800 MPM

- Machine Dimensions: Length 58' 2" (17.7 Mtr)for 120 drums,Width 6'6" (1.98 Mtr),Height 7'6" (2.28 Mtr)-(Including Blower, Trolleys & Suction)

- Power required: 10 H. P. Standard Machine 11.5 H. P. with Blower 14.5 H. P. with Blower & Suction arrangement

OUTSTANDING FEATURES

- Special Builder Cam Lever attachment is provided for getting required shape for 3.30 / 5.57 / 4.20 Paper Cones

- Special graded cast iron frames and steel covers for superior strength and long rust free life

- Slow falling attachment to avoid damage to drums by reducing the impact on the drums

- Automatic Mechanical Stop Motion with Hardened Steel / Chilled C. I. Internal parts complete enclosed in frame to ensure trouble free performance

- Standard make electric motors and components

- Best quality double sealed ball bearings

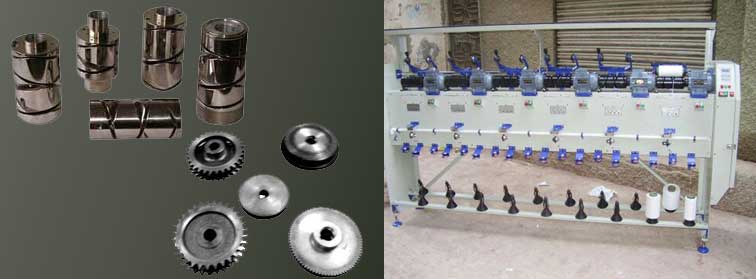

- Dynamically balance Bakelite / Metallic Traverse Drums of 3 �" diameter

- Highly polished and ground steel shaftings for drive shafts

- A specially designed make and brake Electro-Mechanical contactor, with silver tipped contacts, with starts / stops the drive shaft 32 times per minute to avoid ribbon formation

- Machine absolutely free from vibration

OPTIONAL ATTACHMENTS

- Yarn-Clearers:Digital Electronic Yarn Clearer Mechanical (Single/Double blade type) Slub Catchers(with/without wax attachment)

- Traverse Drums:

95mm dia Metallic Aluminium Hard Anodised drums or

Steel Covered Bakelite Drums/plain Bakelite Drums

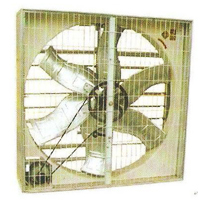

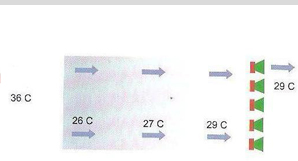

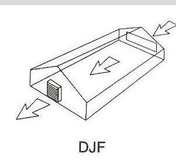

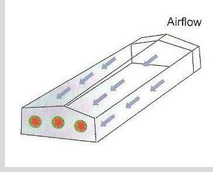

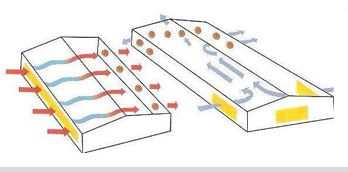

- Traveling Blower:

Over-head To & Fro type Heavy Duty Blower / Overhead Travelling Cleaner with Suction Device.

- Special Supply System:

Universal supply bobbin peg with six sliding trolleys for storing bobbins with splicer box attaching facility.Custom made pneumatic air splicer.

CHEESE WINDING MACHINE

GENERAL SPECIFICATIONS

- No. of Spindles: 8-192 Spindles (or in multiples of 8 Spindles upto 192 Spindles).

- Package Option: The Machine is suitable to wind Plastic tubes,wooden tubes,paper tubes.Soft Dyeing Packages on Dye Springs or S. S. Cones

- Yarn Suitability: Cotton / Synthetics / Blended or Woolen Yarn.

- Winding Speed: A Choice of 3 Speeds 400 / 500 / 600 MPM available options from 2ply to 5ply

- Machine Dimensions: Length 58' 2" (17.7 Mtr)for 120 drums, Width 6'6" (1.98 Mtr), Height 7'6" (2.28 Mtr)-(Including Blower, Trolleys & Suction)

- Power required: 10 H. P. Standard Machine 11.5 H. P. with Blower 14.5 H. P. with Blower & Suction arrangement

OUTSTANDING FEATURES

- Special Brake Lever attachment is provided for getting required stop motion of tubes/springs

- Special graded cast iron frames and steel covers for superior strength and long rust free life

- Automatic Mechanical Stop Motion with Hardened Steel / Chilled C. I. parts for smooth running

- Standard make electric motors and components

- Best quality double sealed ball bearings

- Dynamically balance Bakelite / Metallic Traverse Drums of 3 1/8" diameter

- Highly polished and ground steel shaftings for drive shafts and center shafts

- A specially designed make and brake Electro-Mechanical contactor, with silver tipped contacts, with starts / stops the drive shaft 32 times per minute to avoid ribbon formation

- Machine absolutely free from vibration

OPTIONAL ATTACHMENTS

- Traverse Drums:79.5mm dia Metallic Aluminium Hard Anodised drums or Steel Covered Bakelite Drums/plain Bakelite Drums Ceramic insert drums also provided

- Traveling Blower:Over-head To & Fro type Heavy Duty Blower / Overhead Travelling Cleaner with Suction Device.

- Lenght measuring :Yarn sensors and cutters can be provided for each ply.

SOFT PACKAGEWINDING MACHINE

GENERAL SPECIFICATIONS

- No. of Spindles: 120 Spindles (or in multiples of 8 Spindles upto 192 Spindles)

Package Option: The Machine is suitable to wind

3.30 / 5.57 / 4.20 Paper / Plastic Cones

Soft Dyeing Packages on Dye Springs or S. S. Cones

Parallel Plastic Tubes for weft feeding of Automatic Looms .

- Yarn Suitability: Cotton / Synthetics / Blended or Woolen Yarn

Winding Speed: A Choice of 3 Speeds 600 / 700 / 800 MPM.

- Machine Dimensions: Length 58' 2" (17.7 Mtr)

Width 6'6" (1.98 Mtr)

Height 7'6" (2.28 Mtr)

(Including Blower, Trolleys & Suction)

Power required: 10 H. P. Standard Machine

11.5 H. P. with Blower

14.5 H. P. with Blower & Suction arrangement.

OUTSTANDING FEATURES

- Special Builder Cam Lever attachment is provided for getting required shape for 3.30 / 5.57 / 4.20 Paper Cones .

- Cast iron frames and frame covers made from polished iron sheets with exclusive paint finish for superior strength and long rust free life.

- Slow falling attachment to avoid damage to drums by reducing the impact on the drums.

- Automatic Mechanical Stop Motion with Hardened Steel / Chilled C. I. Internal parts complete enclosed in frame to ensure trouble free performance.

- Standard make electric motors and components

- Best quality double sealed ball bearings

- Dynamically balance Bakelite / Metallic Traverse Drums of 3 �" diameter

- Highly polished and ground steel shaftings for drive shafts and center shafts.

- A specially designed make and brake Electro-Mechanical contactor, with silver tipped contacts, with starts / stops the drive shaft 32 times per minute to avoid ribbon formation is a unique feature of VIJAY Cone Winders.

- Machine absolutely free from vibration

OPTIONAL ATTACHMENTS

- Yarn-Clearers:

�PREMIER� Digital Electronic Yarn Clearers

�VIJAY� Single/Double Slub catchers.

- Traverse Drums:

95mm dia Metallic Aluminium Hard Anodised drums or Bakelite Drums.

- Traveling Blower:

Over-head To & Fro type Heavy Duty Blower / Overhead Travelling Cleaner with Suction Device.

- Waxing Attachment:Available with any type of yarn-clearer.

- Special Supply System:Universal supply bobbin peg with six sliding trolleys for storing bobbin